Ever observed cranes lifting heavy loads, excavators digging and scooping earth or the extension and retraction of landing gears in an aircraft? They all have one thing in common: they are driven by hydraulics. In all of them, the input power, from a combustion engine or an electric source, is converted into flexible mechanical power. The apparatus that achieves this conversion is the hydraulics.

What are hydraulics?

A hydraulics system is based on the simple principle of Pascal’s law, named for the 17th century French scientist Blaise Pascal. The law states that when pressure is applied to an incompressible fluid, it is transmitted equally in all directions throughout the fluid. Pressure here is simply the amount of force per unit area.

In a hydraulic system, pressure is created by applying force to a fluid. And because it is subsequently transmitted equally in all directions, a small force applied over a small area can create a much larger force over a larger area. The illustration belowshows how.

An illustration of a hydraulic jack. The figures are illustrative.

| Photo Credit:

Public domain

A small force applied at one end can be used to generate a much larger force at the other end just by having a larger area of contact. There’s no need to change the pressure. This is perhaps the simplest use of hydraulics. There are many more actions that a hydraulic system can perform than just lifting.

Hydraulics have many advantages over mechanical methods of transmitting energy. The principal ones are smooth movements, high power to weight ratio, better heat dissipation, smooth controls, and higher precision.

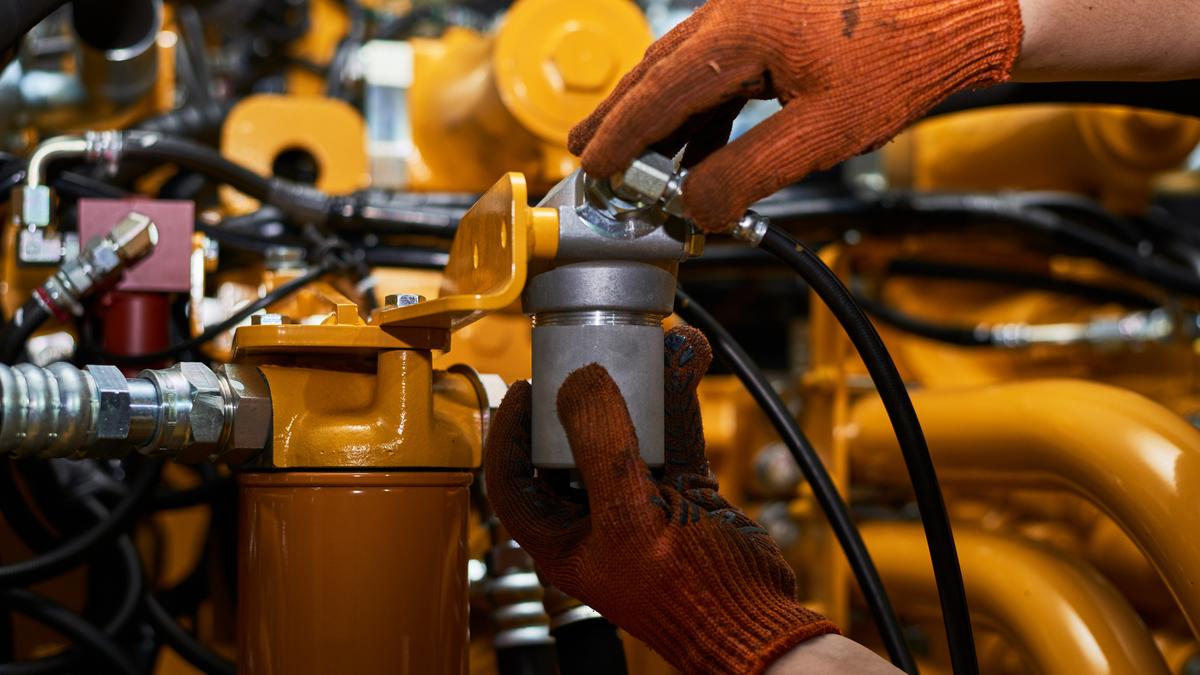

What are the parts of a hydraulic system?

There are six general components in every hydraulic system.

(i) Pumps: to convert the input mechanical energy into pressure and generate a flow

(ii) Pipes: to carry the oil to the end points of the application and return to the tank

(iii) Valves: to control the flow and direction of the pressurised oil

(iv) Linear actuators or rotary actuators: to deliver the work at the output end

(v) Tank (with filters): to hold the hydraulic oil

(vi) Sensors or switches: whenever needed from an operational or safety perspective.

Of these, the defining components are the pumps, valves, and the actuators (plus the sensors/switches wherever required). The tanks, filters, and pipes are only to hold and convey the elements and play no dynamic role.

Larger systems may also have a way to cool the oil, since it heats up during continuous operation. Likewise, in very cold environments, a heater is also added to the circuit to warm up the oil before starting so that the oil is sufficiently less viscous.

There are different types of pumps, including gear type, axial piston type, variable delivery type, and so on. The type of pump used is based on the pressure and flow rate the application needs. Pumps can be driven by electrical motors or by coupling with a combustion engine (called a power take-off unit).

Valves are classified broadly based on their actions on the oil: flow control, direction control, and pressure control. In very basic systems, valves can be operated manually; in others, they are controlled electrically.

Actuators, the last major element in the circuit, deliver the actual output at the application endpoint. The most common one in use is the linear actuator, also known as a hydraulic cylinder. In this set up, a cylindrical chamber has a rod sliding in and out. These rods are visually bright due to the chrome plating over them and are clearly visible on earth-moving equipment or a crane in action. The pressure of the oil fed in determines how much force or power the rod can deliver. The flow rate of the oil determines how fast or slow the rod moves. And the direction of the oil’s flow determines which way the rod moves.

In a rotary actuator (also known as a hydraulic motor) the output is rotating rather than linear. The rotary motion can be used to drive applications, for example, a winch wheel. The flow rate, pressure and direction of oil flow determine the speed of rotation, torque, and direction of rotation of the output shaft, respectively.

What are applications of hydraulics?

Hydraulics have a broad base of applications today, from agriculture to waste management, from automation to wind turbines. They can be used for both mobile equipment — cranes, excavators, etc. which move on wheels or tracks — and static applications such as a hydraulic press, moulding machines, windmills, etc. wherein the main equipment is static. Worldwide, hydraulics constitute a $45-50 billion market and is growing steadily.

With rapid developments in electronics and electrification today, hydraulic systems are also changing to take advantage. They are equipped with sensors to track movement, temperature, pressure, flow, oil contamination, etc. While many of the changes are focused on improving safety, some of the data collected is also often used to improve the system’s performance and to carry out predictive maintenance.

They have room for improvement as well. For example, hydraulic systems have an overall energy efficiency (from engine output to usage endpoint) of 30-40%. Engineers and scientists are doing a lot of work to improve this figure while keeping in mind environmental regulations and needs. But even as these actions continue, there is no system to beat the prevailing advantages of hydraulics. There have been attempts to use electrical setups in place of hydraulics but they have been limited to smaller systems. Hydraulics still triumphs as the size of operations and complexities go up.

R. Vasudevan has over two decades’ experience in the manufacture and sale of hydraulic components.

Published – June 18, 2025 06:45 am IST